< Previous Chiaravalli Gearboxes and Motors | Products index | Next Chiaravalli Gearboxes and Motors >

CHM/CHM - PERFORMANCE WITH 4-POLE MOTORS 1400 REVS. INPUT

1200 1.2 0.09* 31

1500 0.9 0.09* 26

1800 0.8 0.09* 23

2400 0.6 0.09* 23

TYPE | i=ratio | n2 r/min | Kw=P1 | Nm=T2 | TYPE | i=ratio | n2 r/min | Kw=P1 | Nm=T2 | |

300 | 4.7 | 0.09* | 31 | 300 | 4.7 | 0.37 | 405 | |||

400 | 3.5 | 0.09* | 28 | 400 | 3.5 | 0.25 | 336 | |||

500 | 2.8 | 0.09* | 34 | 500 | 2.8 | 0.25 | 307 | |||

600 | 2.3 | 0.09* | 31 | 600 | 2.3 | 0.18 | 362 | |||

CHM | 750 | 1.9 | 0.09* | 34 | 750 | 1.9 | 0.18 | 391 | ||

025/030 | 900 | 1.6 | 0.09* | 31 | 900 | 1.6 | 0.18* | 325 |

CHM 040/075

1200 1.2 0.18* 359

1500 0.9 0.09 360

1800 0.8 0.09 404

2400 0.6 0.09* 330

TYPE i=ratio n2 r/min Kw=P1 Nm=T2

300 4.7 0.09* 70

400 3.5 0.09* 63

500 2.8 0.09* 57

600 2.3 0.09* 72

TYPE i=ratio n2 r/min Kw=P1 Nm=T2

300 4.7 0.37 405

400 3.5 0.37 523

500 2.8 0.37 550

600 2.3 0.37 605

CHM 030/040

750 1.9 0.09* 72

900 1.6 0.09* 73

1200 1.2 0.09* 65

1500 0.9 0.09* 73

1800 0.8 0.09* 73

2400 0.6 0.09* 65

CHM 040/090

750 1.9 0.25 538

900 1.6 0.25 533

1200 1.2 0.18 629

1500 0.9 0.18 588

1800 0.8 0.18* 492

2400 0.6 0.18* 625

48 TYPE i=ratio n2 r/min Kw=P1 Nm=T2

300 4.7 0.18 142

CHM/CHM - PERFORM. WITH 4-POLE MOTORS - 1400 REVS. INPUT

400 3.5 0.18 127

500 2.8 0.09 123

600 2.3 0.09 143

TYPE i=ratio n2 r/min Kw=P1 Nm=T2

300 4.7 0.75 871

400 3.5 0.75 1013

500 2.8 0.55 984

600 2.3 0.55 1062

CHM 030/050

750 1.9 0.09 148

900 1.6 0.09* 141

1200 1.2 0.09* 118

1500 0.9 0.09* 139

1800 0.8 0.09* 155

2400 0.6 0.09* 124

CHM 050/110

750 1.9 0.55 1128

900 1.6 0.37 1079

1200 1.2 0.25 943

1500 0.9 0.25 1064

1800 0.8 0.25 1075

2400 0.6 0.18 1001

TYPE i=ratio n2 r/min Kw=P1 Nm=T2

300 4.7 0.22 210

400 3.5 0.18 222

500 2.8 0.18 205

600 2.3 0.18* 208

TYPE i=ratio n2 r/min Kw=P1 Nm=T2

300 4.7 1.50 1789

400 3.5 1.10 1519

500 2.8 1.10 1629

600 2.3 0.75 1631

CHM 030/063

750 1.9 0.18* 216

900 1.6 0.09 200

1200 1.2 0.09 236

1500 0.9 0.09* 204

1800 0.8 0.09* 202

2400 0.6 0.09* 220

CHM 063/130

750 1.9 0.75 1804

900 1.6 0.75 1826

1200 1.2 0.55 1705

1500 0.9 0.37 1674

1800 0.8 0.37 1698

2400 0.6 0.25 1624

N.B. The powers marked with an asterisk are higher than those that the gear allows, therefore the applicative choice must be made in accordance with the torque and not the power.

The gear ratios are those most frequently requested. It is possible to obtain multiple combinations using the various ratios of the two single gears. CHM 63/150 on request

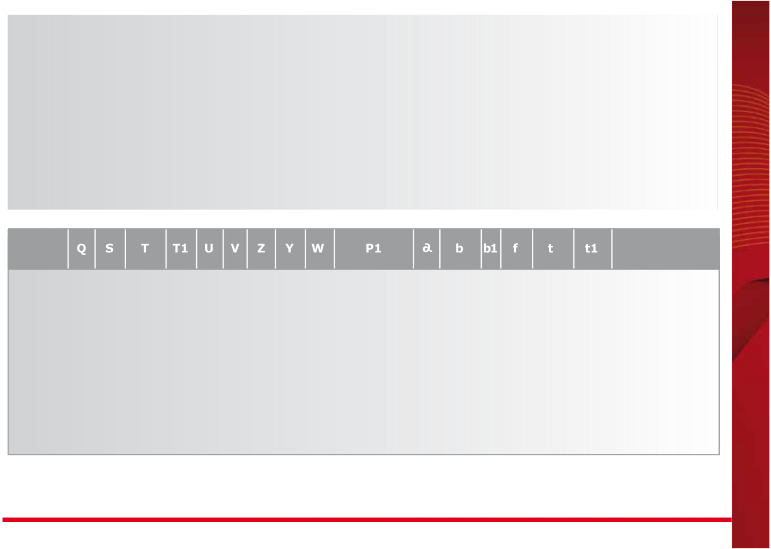

T1

I1

I

V V

D

R

I2 W

t1

b1 f

CHM-CHM | B | A | F | C1 | D(H7) | d(j6) | G | H | R1 | R | R2 | L | L1 | I | I1 | C | I2 | N(h8) | E1 | E2 | P |

025/030 | 54 | - | 80 | 70 | 14 | - | 97 | 32 | 45 | 63 | - | 40 | 35 | 30 | 25 | 56 | 65 | 55 | 29 | 22.5 | 6 |

030/040 | 70 | 20 | 100 | 80 | 18 | 9 | 121.5 | 43 | 55 | 78 | 51 | 50 | 40 | 40 | 30 | 71 | 75 | 60 | 36.5 | 29 | 6.5 |

030/050 | 80 | 20 | 120 | 80 | 25 | 9 | 144 | 49 | 55 | 92 | 51 | 60 | 40 | 50 | 30 | 85 | 85 | 70 | 43.5 | 29 | 8.5 |

030/063 | 100 | 20 | 144 | 80 | 25 | 9 | 174 | 67 | 55 | 112 | 51 | 72 | 40 | 63 | 30 | 103 | 95 | 80 | 53 | 29 | 8.5 |

040/075 | 120 | 23 | 172 | 100 | 28 | 11 | 205 | 72 | 70 | 120 | 60 | 86 | 50 | 75 | 40 | 112 | 115 | 95 | 57 | 36.5 | 11 |

040/090 | 140 | 23 | 208 | 100 | 35 | 11 | 238 | 74 | 70 | 140 | 60 | 103 | 50 | 90 | 40 | 130 | 130 | 110 | 67 | 36.5 | 13 |

050/110 | 170 | 30 | 252.5 | 120 | 42 | 14 | 295 | - | 80 | 155 | 74 | 127.5 | 60 | 110 | 50 | 144 | 165 | 130 | 74 | 43.5 | 14 |

063/130 | 200 | 40 | 292.5 | 144 | 45 | 19 | 335 | - | 95 | 170 | 90 | 147.5 | 72 | 130 | 63 | 155 | 215 | 180 | 81 | 53 | 16 |

063/150 | 240 | 40 | 340 | 144 | 50 | 19 | 400 | - | 95 | 200 | 90 | 170 | 72 | 150 | 63 | 185 | 215 | 180 | 96 | 53 | 18 |

49

CHM-CHM

CHM-CHM/CHMR-CHM - DIMENSIONS OF COMBINED GEARS

Weight in Kg. excluding motor

025/030 | 75 | 44 | 57 | 48 | 5 | 18 | 27 | 100 | 44 | M6x11(n.4) | 90° | 5 | - | - | - | - | 2.5 |

030/040 | 87 | 55 | 71.5 | 57 | 6.5 | 26 | 35 | 120 | 60 | M6x8(n.4) | 45° | 6 | 3 | - | 20.8 | 10.2 | 3.9 |

030/050 | 100 | 64 | 84 | 57 | 7 | 30 | 40 | 130 | 70 | M8x10(n.4) | 45° | 8 | 3 | - | 28.3 | 10.2 | 5.0 |

030/063 | 110 | 80 | 102 | 57 | 8 | 36 | 50 | 145 | 85 | M8x14(n.8) | 45° | 8 | 3 | - | 28.3 | 10.2 | 7.8 |

040/075 | 140 | 93 | 119 | 71.5 | 10 | 40 | 60 | 165 | 90 | M8x14(n.8) | 45° | 8 | 4 | - | 31.3 | 12.5 | 11.5 |

040/090 | 160 | 102 | 135 | 71.5 | 11 | 45 | 70 | 182 | 100 | M10x18(n.8) | 45° | 10 | 4 | - | 38.3 | 12.5 | 15 |

050/110 | 200 | 125 | 167.5 | 84 | 14 | 50 | 85 | 225 | 115 | M10x18(n.8) | 45° | 12 | 5 | M6 | 45.3 | 16.0 | 39.2 |

063/130 | 250 | 140 | 187.5 | 102 | 15 | 60 | 100 | 245 | 120 | M12x21(n.8) | 45° | 14 | 6 | M6 | 48.8 | 21.5 | 70 |

063/150 | 250 | 180 | 230 | 102 | 18 | 72 | 120 | 275 | 145 | M12x21(n.8) | 45° | 14 | 6 | M6 | 53.8 | 21.5 | 100 |

N.B. For the side flange and double extended input worm dimensions see the corresponding size of the CHM models.