< Previous Sew Eurodrive products | Products index | Next Sew Eurodrive products >

Regenerative power supply and motor inverter up to 315 kW

Regenerative power supply MOVIDRIVE MDR61B

Features | – Energy-efficient and optimized overall concept: MOVIDRIVE B product series extended by regenerative power supply units and corresponding motor inverters in the power range from 160 to 315 kW – Particular interesting for applications with potential energy, such as in hoists, cranes and gantries, or in trolleys with high kinetic energy produced through electrical braking | |

Functions | – Used as central regenerative power supply for connected standard inverters or motor inverters – Energy is fed back into the grid when the application is operating as a generator, e.g. during electrical braking – Braking energy is no longer converted into heat but is fed back into the grid for further use | |

Advantages | – Significant reduction of the overall energy consumption / of CO emissions / of energy costs 2 – No braking resistors are required - No investment costs for braking resistors - No installation effort for external braking resistors - No heating up of the environment through braking resistors – Sinusoidal line current = controlled energy recovery – With coated printed-circuit boards as standard for demanding ambient conditions – Simple installation and wiring: integrated PWM filter / integrated choke / integrated and automatic DC link precharge / in- tegrated line contactor – Modular power section, which means not the entire unit needs to be replaced in the event of service – EMC limit value class C3 (EN 61800-3) with the standard unit - On supply system end: without any measures i no external line filter necessary - On motor end: with shielded motor cables and output choke | |

Type designation | MDR61B1600-503-00/L | MDR61B2500-503-00/L |

Connection voltage | 3× AC 380 V – 500 V | |

Nominal power kW | 160 | 250 |

Line current/nominal motor power IN A | 250 | 400 |

Maximum continuous power | 125% I N | |

Overload capacity | 150% I for 60 s N | |

External accessories for control cabinet installation | – Mounting base – Air duct – Connection kit – Touch guard (IP20 kit) – DC link coupling | |

Motor inverter MOVIDRIVE MDX62B

Features | – Energy-efficient and optimized overall concept: MOVIDRIVE B product series extended by regenerative power supply units and corresponding motor inverters in the power range from 160 to 315 kW – Particular interesting for applications with potential energy, such as in hoists, cranes and gantries, or in trolleys with high kinetic energy produced through electrical braking | ||

Functions | – MOVIDRIVE B standard inverter without input stage for connection to the MOVIDRIVE B MDR61B regenerative power supply | ||

Advantages | – Cost-optimized MOVIDRIVE B standard inverter without input subassemblies – Simple installation – DC link connection via conductor rail – All MOVIDRIVE B option cards can be used | ||

Type designation | MDX62B1600-503-4-0T/L | MDX62B2000-503-4-0T/L | MDX62B2500-503-2-0T/L |

Connection voltage | Connection to regenerative power supply MDR61B | ||

Nominal power kW | 160 | 200 | 250 |

Line current/nominal motor power IN A | 300 | 380 | 470 |

Maximum continuous power | 125% I N | ||

Overload capacity | 150% I for 60 s N | ||

Internal options | Utilization of all MOVIDRIVE B option cards for connection to fieldbus systems and evaluation of motor encoders or distance encoders (see MOVIDRIVE B options) | ||

External accessories for control cabinet installation | – Mounting base – Air duct – Connection kit – Touch guard (IP20 kit) – DC link adapter – DC link coupling | ||

06

6.1 Control cabinet installation

: Energy efficiency in the control cabinet

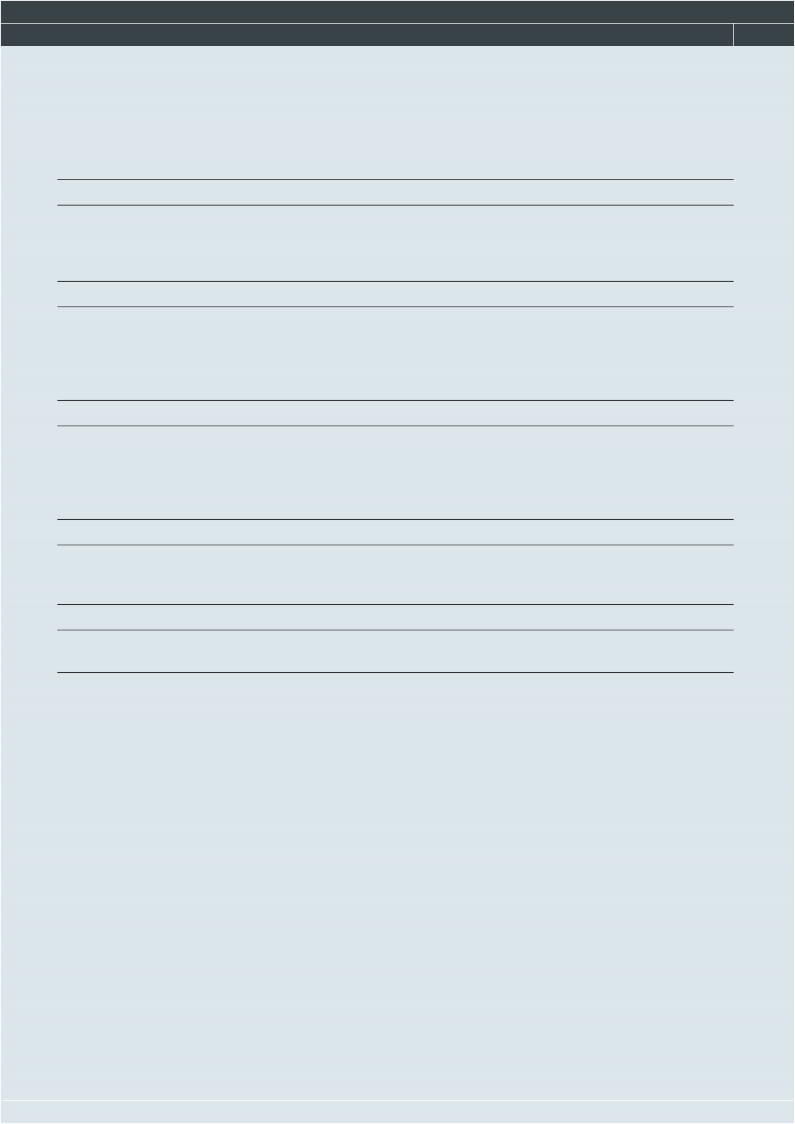

The perfect drive solution for applications from simple speed control to dynamic positioning | Process adaptation | Energy saving function | DC link coupling | Regenerative power supply | Thermally controlled fans |

MOVITRAC LTE-B – Compact range of functions for simple applications | ✔ | ✔ | ✔ | ||

MOVITRAC LTP-B – Adjusted range of functions for simple applications | ✔ | ✔ | ✔ |

| ✔ |

MOVITRAC B – Compact design with complete range of functions – Cost-efficient choice for standard tasks | ✔ | ✔ | ✔ | ✔ | ✔ |

MOVIDRIVE B – High basic functionality with wide range of options – Cost-efficient choice for complex systems | ✔ | ✔ | ✔ | ✔ | ✔ |

Process adaptation

– Almost every process can be adapted to the actual demand thanks to infinitely variable speed and torque control, which makes the process more energy-efficient. Depending on the application, this saves up to 70% of energy.

– More energy-saving potential can be tapped in applications with periodic acceleration and deceleration through energy-efficient motion sequences. Maximum acceleration, speed and braking deceleration are not always necessary.

Energy-saving function

– The energy-saving function of MOVITRAC LTE-B, LTP-B and MOVITRAC B as well as MOVIDRVE B offers advantages when the application has to be operated in the part-load range and dynamic properties are not a main requirement when load changes occur.

– The dynamic adjustment of the magnetization current enables the motor to be operated with optimum efficiency in every operating point. The energy consumption is reduced by up to 30% depending on the application.

– The energy-saving function ensures optimum efficiency of the drive especially in conjunction with an energy-efficient motor.

DC link coupling

– By connecting the DC links of several inverters, regenerative energy of one drive can be used directly as motor energy in another drive.

– This measure can reduce energy consumption from the supply system if the drive sequences are segmented and suitable travel profiles have been selected.

– MOVI-PLC: In storage and retrieval systems, the decentralized controller allows for controlling the travel profile in an intelligent manner and in this 06

way achieves optimum energy coupling.

Regenerative power supply

– A regenerative power supply unit feeds back the regenerative energy of a drive into the supply system.

– The released braking energy is not dissipated via braking resistors but fed back into the supply system, which saves energy.

– This is especially effective in hoists as well as storage and retrieval units.

Thermally controlled fans

– The fans are switched on only when actual waste heat is generated. Not only does this lower energy consumption, it also increases the service life of the fan.