< Previous Rexnord Marbett Components for beverage | Products index | Next Rexnord Marbett Components for beverage >

Marbett Component Solutions

for Beverage End-Users

![]()

Contents

• Why this Catalogue

• Solutions for Chain Wear Strips Page 5

Quality and Productivity Applications and Suggested Products

• Solutions for Chain Return Page 15

Quality and Productivity Applications and Suggested Products

• Solutions for PET Air Conveyors Page 27

Quality and Productivity Applications and Suggested Products

• Solutions for Bearings Page 33

Quality and Productivity Applications and Suggested Products

![]()

The company The industries served

Rexnord is a global company supplying many industries with power transmission and conveying components. The product offering ranges from roller chains, couplings and geared products to conveyor chains, belts and components.

The head office is based in the United States, with several divisions all over the world. The Rexnord FlatTop division is manufacturing conveyor chains, belts and components.

Rexnord is fully committed to meet customer expectations; huge knowledge of the business reduces maintenance costs, eliminates redundant inventories and prevents downtime, all in close co-operation with OEMs and end users. This is a

result of Rexnords focus on product development, application engineering, operations and customer service.

Rexnord FlatTop Europe represents 3 strong brands: Rexnord, MCC and Marbett.

With production facilities in ‘s-Gravenzande and Correggio,

sales offices in The Netherlands, Italy, a large sales group for local service in many countries and distributors all over the world, Rexnord is always close to its customers.

In this way a fast and reliable delivery is guaranteed.

Rexnord chains and belts are being used to convey a wide variety of products: bottles, cans, boxes, crates, tires, loose food, glass jars, PET containers, trays; shortly every transport in production halls in virtually any industry.

The product range has been split up over two catalogues, one for Rexnord/MCC Table Top/MatTop chains and one for Marbett conveyor components.

As the handling specialist in the field of conveying, the Rexnord product portfolio is providing solutions for complete lines in several industries in order to improve productivity.

In beverage industry palletizers, depalletizers, washers, labelers, fillers, pasteurizers, inliners, outfeeds, elevators and accumulation tables are

equipped with slatband chains, curves, sprockets, belts, bearings, leveling elements and many more conveyor components.

For the container manufacturing industry special products and materials are available, such as abrasion resistant polyamide for glass plants, vacuum chains for can making and gripper chains for vertical transport.

For food industry applications modular belts and components with Microban antibacterial protection are

used in deboning, grading and trimming lines for meat, poultry and seafood. A wide range of products is also offered for blanchers, cookers, washers, coolers and processing lines

in fruit, vegetables, bakery, confectionary etc. And many more products are available for the handling of packed food.

In automotive industry the products are engineered to meet the most demanding applications, such as rubber processing and tire handling.

![]()

![]()

This is just a short selection of the applications in which Rexnord products are being used. Among others they have also found their way into pharmaceutical production lines, battery manufacture, paper and cardboard production.

![]()

Rexnord and MCC TableTop chains and MatTop belts

The product line can be split up into:

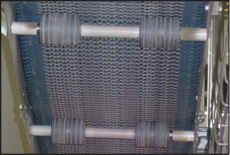

• Steel slatband chains

In various materials ranging from carbon steel to special stainless steel with better wear and sliding properties; types straight running, sideflexing tab, bevel and Magnetflex, with

and without rubber top.

• Plastic slatband chains

Wide range of materials and various executions; single hinge, double hinge, heavy duty, vacuum, lbp rollers and rubber top.

• Plate Top and Gripper chains

Based on the Rexnord roller chains in both stainless and carbon steel; Plate Top chains have steel or plastic top plates; Gripper chains have different types of rubber inserts.

• Case conveyor and Multiflex chains Different types of acetal for both straight running and sideflexing transport of products varying from heavy crates to small juice packs.

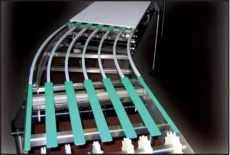

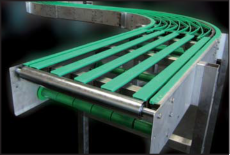

• Curves

Magnetflex, Tab and bevel, as well as straight tracks to support the chain in all parts of the line; there are many standard versions besides the ability to make any special curve needed

in your applications with short delivery times.

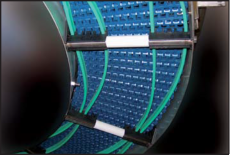

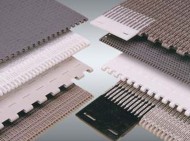

• Modular belts

Pitches differ from 0.5 to 2.25 inch to suit any application. Most series have both closed and open top executions; some also available with rubber top for inclined conveying.

Marbett conveyor components

The product line can be split up into:

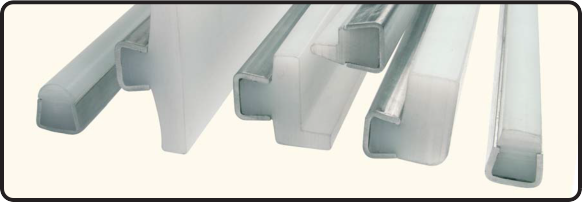

• Chain guide components

Profiles, corner tracks, straight tracks, return rollers, serpentine, plugs for connections.

• Product handling components Guide rails, roller guides, guide

rail clamps, guide rail brackets and connecting clamps in plastic or stainless steel.

• Frame support components Side mounting top brackets, bearing heads, support bases and connecting joints, stainless steel components.

• Supporting and leveling elements Different versions in steel and plastic,

articulated and fixed, with and without gripper bottom and vibration absorbing feet.

• Self-aligning bearings Square, oval, pillow block, side flange,

take-up, round, and other executions, all with open and closed unit. Lubricated for life versions are also available.

• Miscellaneous components Line control elements, hinges, locks, knobs, modular transfer roller plates, rollers, tensioners, nozzles, cable carriage chains, shaft collars and nose-over bars.

Why this catalogue

• We have a big Conveyor Components catalogue that is made for equipment manufacturers mainly

![]()

• With this small catalogue we want to concentrate on components that End-Users need to replace to keep bottling line productivity as high as possible

![]()

![]()

4

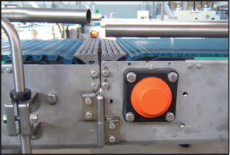

Solutions for Chain Wear Strips

• Wear strips are vital for chain’s wear life

- Old wear strips might look like new, with no thickness change, but microscopic

abrasive particles coming from conveyed products or chains or environment are

often embedded.

They will cause premature wear on the new chains

- Why risk 100 $ of chain to save 20 $ of wear strips? ( prices just for reference )

• Check what you are buying: Outstanding Low Friction-Low Wear UHMWPE

- 5.6 million “density” = stronger wear resistance, better friction.

- Most wear strips on the market use materials with < 4 millions density

• machined (worse finishing) profiles ( mostly < 2 millions )

• standard extrusion profiles ( less wear resistant properties, mostly < 2 millions )

- ULF Premium Quality, Self Lubricated version with Solid Lubricant also available.

• Results: Higher Productivity and Cost Saving

- Longer Chain Wear Life - Reduced Maintenance-Downtimes

- Longer Guide Wear Life

- Reduced energy consumption

- Limited or null lubrication possible

![]()

• Rexnord-MCC chains reach best performances by Marbett wear strips

![]()

![]()

![]()

![]()

![]()

5

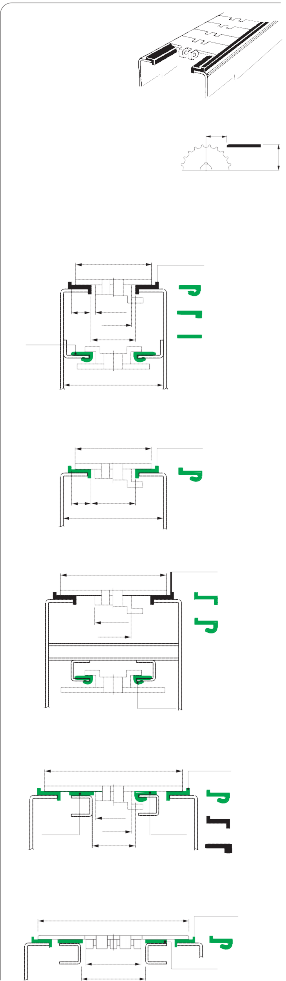

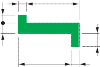

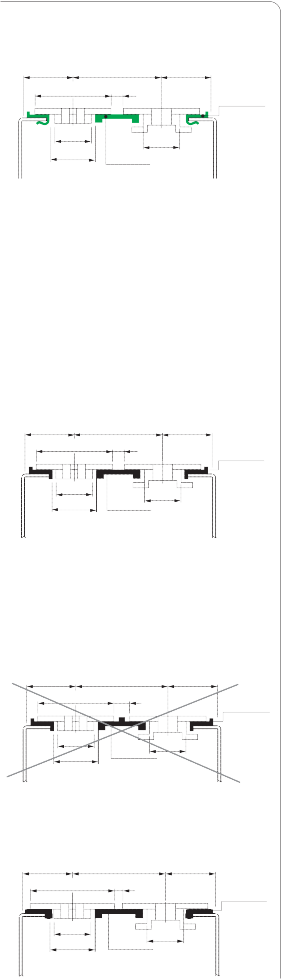

Part. S0262

![]() Chain - guide profile

Chain - guide profile

Packaging

• Material

Polyethylene UHMWPE with molecular

3 20

Colour

metres

Code

![]()

density 5.600.000.

Black | 45 | 63651 |

Green | 45 | 632272 |

• Linear expansion

3

coefficient

![]()

4

2 x 10 -4

![]()

5

Calculation of thermal

20 3

Reinforced version

- Standard packaging : coil.

expansion see page 38.

• Operating temperature + 6

In air (- 40 to + 80 C). P 0

+ 1

0

In hot water (+ 70 C).

H

• Position of guides. See page 39.

• TableTop® chains series 812 - 815 - 820 - 831 - 881TAB - 8811TAB - 879TAB - 880TAB

Chain width 82,5 mm (K 325) / Guide clearance 45 mm

Part. S0261

![]()

20

![]()

![]() Chain - guide profile

Chain - guide profile

Packaging

With

Code

Without

Part./Art. Réf. 261

82,5

20 42,1

43

45

100

Part./Art. Réf. S0262

Part./Art. Réf. S0261

Part./Art. Réf. S0243

Part./Art.

Réf. S0244

![]()

metres

Microban® Microban®

3

10

40 651992

65681

Chain width 82,5 mm (K 325) / Guide clearance 49 mm

![]()

TM ®

antibacterial protection

![]()

- Applicable to 2,5 to 3,5 mm thick sheet metal.

- Colour : white ( with Microban® ), green ( without Microban® ).

- Standard packaging : coil.

82,5

18 49

100

Part./Art. Réf. S0241

Part./Art. Réf. S0251

Chain width 114,3 mm (K 450)

114,3

Part./Art. Réf. S0262

Part. S0243

![]()

20

![]()

![]() Chain - guide profile

Chain - guide profile

Packaging

With

Code

Without

42,1

43

Part./Art.

Part./Art. Réf. S0241

Part./Art. Réf. S0251

![]()

metres

Microban® Microban®

Réf. S0261

90 698642

63701

![]()

Chain width 152,4 mm (K600), 190,5 (K750)

2

3

![]()

TM ®

antibacterial protection

- Colour : white ( with Microban® ), green ( without Microban® )

- Standard packaging : coil.

Part./Art. Réf. 244

152,4-190,5

42,1

43

45

Part./Art. Réf. 261

Part./Art. Réf. S0241

Part./Art. Réf. S0251

Part./Art. Réf. S0262

Part./Art. Réf. S0386

![]()

![]() Best choice Standard

Best choice Standard

• TableTop® double hinge chain series 802 - 805 Chain width 190,5 mm (K 750)

![]() On request : minimum quantity may apply. Consult our Customer Service for availability.

On request : minimum quantity may apply. Consult our Customer Service for availability.

190,5

Part./Art.

Réf. S0241

Part./Art.

![]()

Item code for order = Part. + Code

6

80,5

82,5

Part./Art. Réf. S0244

Réf. S0251

2,5

• TableTop® double hinge chain series 821 Chain width 190,5 mm (K 750)

![]() Chain - guide profile

Chain - guide profile

Packaging

Part. S0241

2,5

2 18

190,5

136,5

Part./Art.

Réf. S0262

Part./Art. Réf. S0241

Part./Art.

Colour

![]()

![]()

![]()

Green Black

metres

80

80

Code

![]()

63641

60356

3

18 2

Chain width 304,8 mm (K 1200).

304,8

Réf. S0251

- Standard packaging : coil.

Part./Art. Réf. S0674

140 4 Part./Art.

Réf. S0262

• TableTop® chains series 882 TAB Chain width 114,3 mm (K 450)

114,3

57,2

60

Part./Art. Réf. S0262

Part./Art. Réf. S0241

Part./Art. Réf. S0251

![]()

Part./Art.

![]() Chain - guide profile

Chain - guide profile

Packaging

Part. S0251

![]()

2 18

Réf. S0261

![]()

Colour

metres

3 2

Code

Chain width 254 mm (K 1000), 304,8 mm (K1200).

Green

10

40 63631

254-304,8 Part./Art.

Réf. S0262

![]()

- Applicable to 2,5 to 3,5 mm thick sheet metal.

- Standard packaging : coil.

Part./Art. 4

Réf. S0674

• PlateTop chains series 1874 - 4874 - 1873

Chain width 82,5 mm (K 325), 114,3 mm (K 450), 152,4 mm

(K 600)

82,5-114,3-152,4

31,75

Part./Art. Réf. S0223

Part./Art. Réf. S0262

Part./Art. Réf. S0241

Part./Art. Réf. S0251

![]() Chain - guide profile

Chain - guide profile

![]()

Part. S0244

34,6

Part./Art. Réf. S0261

![]()

Colour

L x H mm

Packaging metres

![]()

H

Code

• Low backline pressure chains series SLBP 882 TAB - SLBP 821 Chain width 95,2 mm (K 375)

Green

20 x 3 60

20 x 5 80

25 x 3 60

63711 L

63691

63721

Part./Art. Réf. S0261

57,2

60

95,2

Black

30 x 3 60

40 x 3 60

![]()

40 x 5 50

20 x 3 60

20 x 5 80

63731

63661

608172

60386

60376

95,2

Part./Art.

Chain width 190,5 mm (K 750)

Réf. S0244

- Standard packaging : coil.

![]()

![]() Best choice Standard

Best choice Standard

190,5

Part./Art. Réf. S0244

![]() On request : minimum quantity may applay. Consult our Customer Service for availability.

On request : minimum quantity may applay. Consult our Customer Service for availability.

![]()

Item code for order = Part. + Code

7

Part. S0825

![]() Chain - guide profile

Chain - guide profile

Packaging

• Material

Polyethylene UHMWPE with molecular

density 5.600.000.

3 21

Colour

![]()

Green

metres

40

Code

![]()

632033

• Linear expansion coefficient

![]()

2 x 10 -4

3 3

- Applicable to 2,5 to 3,5 mm thick sheet metal.

10

- Can be used in combination with Part. S0784.

- Standard packaging : coil.

Calculation of thermal expansion see page 38.

• Operating temperature + 6

In air (- 40 to + 80 °C). P 0

+ 1

0

In hot water (+ 70 °C).

H

• Position of guides. See page 39.

Chain width 82,5 mm ( K 325 ) / Pitch 85 mm

50 85 50

82,5 2,5

42,1 43

Part./Art. Réf. S0825

![]()

Part. S0822 Chain - guide profile

44,5

Part./Art. Réf. S0784

4 22

Colour

Green

Length metres

3

![]()

6

Code

632713

632723

![]()

Chain width 84 mm pitch 85 mm

![]()

50 85 50

6

84 1

Part./Art. Réf. S0822

4

10,5

- Can be used in combination with Part. S0362.

- Standard packaging : bars of 3 and 6 metres.

- Packaging : 96 metres.

FTDP1000

Part./Art.

FTM 1060

Réf. S0362

• TableTop® chains series 820 - 880TAB

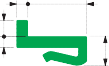

Part. S0386

![]() Chain - guide profile

Chain - guide profile

Chain width 87 mm ( K 343 ) / Pitch 88 mm

Multi strand conveyors, with 82,5 mm width chains and pitch 88 mm, can be modified to convey PET bottles with pethal bottom or other unstable products.

50 88 50

82,5 5,5

![]()

![]()

4

Colour

Packaging metres

Code

![]()

42,1

Part./Art.

Réf. S0262

![]()

20 | 5 | ||

3 |

Black 40 66096

![]()

- Can be used in combination with Part. S0387.

- Standard packaging : coil.

43

45 Part./Art.

Réf. S0263

Reinforced version

Change chains ( from 82,5 mm to 87 mm width ) and wear strip, in this way the Gap between chains is reduced ( from 5,5 mm to 1 mm ) while the conveyor frame is unchanged ( pitch 88 mm )

![]() Best choice

Best choice ![]() Standard

Standard

![]() On request : minimum quantity may apply. Consult our Customer Service for

On request : minimum quantity may apply. Consult our Customer Service for

50 88 50

87 1

42,1 43

Part./Art. Réf. S0386

availability.

![]()

Item code for order = Part. + Code

45 Part./Art.

Réf. S0387

8

Chain width 82,5 mm ( K 325 ) / Pitch 85 mm

![]()

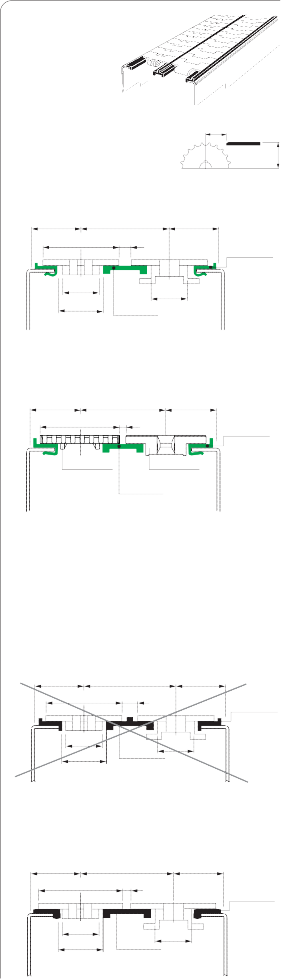

Chain - guide profile Part. S0784

50 85 50

82,5 2,5

42,1 43

Part./Art. Réf. S0825

Colour

Green Black

Length metres

![]()

3

6

![]()

3

6

30,5 | ||||

5 | 5 | |||

40,5 | ||||

3

Code

![]()

620513

7

620523

620533

620543

44,5

Part./Art. Réf. S0784

![]()

- Standard packaging : bars of 3 and 6 metres.

- Packaging : 96 metres.

Chain width 82,5 mm ( K 325 ) / Pitch 85 mm 50 85 50

82,5 2,5

42,1

Part./Art. Réf. S0262

![]()

Length metres | Code |

3 | 694331 |

6 | 67435 |

3 | 694341 |

6 | 61726 |

Chain - guide profile Part. S0362

31 | |||

5 | 5 | ||

41 | |||

4

Colour ![]()

![]()

![]()

![]()

![]()

![]()

5

Green

![]()

44,5

43

Part./Art.

Réf. S0362

Black

![]()

- Standard packaging : bars of 3 and 6 metres.

- Packaging : 96 metres.

Reinforced version

• TableTop® chains series 820 - 880TAB Chain width 87 mm ( K 343 ) / Pitch 88 mm

Multi strand conveyors, with 82,5 mm width chains and pitch

88 mm, can be modified to convey PET bottles with pethal bottom or other unstable products.

50 88 50

82,5 5,5

42,1 43

Part./Art. Réf. S0262

![]()

Chain - guide profile Part.

![]()

4

Length

![]()

30,5 | |||

6 | 6 | ||

43 | |||

Colour metres Code ![]()

S0387

45 Part./Art.

Réf. S0263

3

Black

6

694351

![]()

![]()

5

66106

Change chains ( from 82,5 mm to 87 mm width ) and wear strip, in this way the Gap between chains is reduced ( from 5,5 mm to 1 mm ) while the conveyor frame is unchanged ( pitch 88 mm )

![]()

- Can be used in combination with Part. S0386.

- Standard packaging : bars of 3 and 6 metres.

- Packaging : 96 metres.

![]()

Reinforced version

50 88 50

87 1

42,1 43

Part./Art. Réf. S0386

![]() Best choice

Best choice ![]() Standard

Standard

![]() On request : minimum quantity may applay. Consult our Customer Service

On request : minimum quantity may applay. Consult our Customer Service

45 Part./Art.

Réf. S0387

for availability.

![]()

Item code for order = Part. + Code

9

For the most demanding bottling and container applications, there is no substitute for the performance and productivity of Rexnord TableTop and MatTop Chains. Since 1938, with the ground-breaking 815 TableTop stainless steel straight-running chain, Rexnord has pioneered innovation in beverage and food conveying that has inspired loyalty and driven specification for Rexnord conveyor chains from customers around the globe.

Line efficiency

Smooth container flow at high speeds is essential to increase line efficiency and preventing product damage. Especially when moving from multiple to single lanes or the reverse, the gentle slide of bottles across ultra-flat, highly polished stainless steel Rexnord chain can contribute significantly to the quality and efficiency of your beverage production line.

Applications in beverage

Rexnord products cover a wide variety of applications like: general conveying of glass bottles one-way and return, PET bottles and other plastic containers, jars, cans 2- and 3-piece, crates, plastic containers, boxes, shrink-wrapped packages.

Product Portfolio

Rexnord offers a comprehensive of conveyor products which include

Metal TableTop chain

Plastic TableTop chain including LBP and Supergrip

Plastic MatTop chain in standard, small pitch and heavy duty alternatives.

Magnetflex Corner tracks as well as alternatives like Tab and Bevel curves

Machined and moulded sprockets

High performance polymer materials & economic alternatives for less demanding applications

Pack and case conveying that offers flexibility of line configurations and total system cost efficiencies can significantly improve productivity at the dry end of filling lines. At the same time, brand extensions, innovative packaging, and light weight packaging materials are driving more demanding performance in pack and case handling. Cases and packs must be protected from damage even as they move rapidly out of case packers and shrink wrap machines and into, around, and out of curves.

That’s why Rexnord’s case and package handling conveying chains come in our modular small pitch, lightduty 15mm 1500 Series to medium duty 25.4mm pitch 1000 Series to the heavy-duty 1 in pitch 1005 Series in both versions for general conveying and in Super Grip / RubberTop™ versions for metering, incline, decline and braking applications. Furthermore the programm includes a comprehensive portfolio of Sideflexing MatTop chains like the versatile 1200-series MatTop. For accumulating conveyor the LBP (Low Backline Pressure) chains offers a solution to a large variety of applications.

With the Rexnord original Heavy Duty TableTop chains for packaging conveying, no other company provides the breadth of conveying solutions for your case and package handling requirements.

Rexnord products are known for their reliable performance in though conditions and challenging applications due to their robustness in design and drive technology. In container making therefore Rexnord products are often the preferred choice for applications like vacuum elevators, high speed (magnetic) conveyors, UV applications, high temperature applications and inspection conveyors.

Rexnord Material innovation

On top Rexnord offers the most comprehensive material portfolio in the market to meet an extensive variety of application requirements. Several applications in glassworks and container making lines combine an abrasive environment with the need for smooth container handling. Often these applications can not be easily lubricated to neutralize the effect of the hard abrasive particles in the environment. Therefore specialized materials can be part of a custom made solution. This is why, besides several proven specialized high performance materials like WX, HP and PS, Rexnords material portfolio is now completed with DKA aramid reinforced material.

Processing and packaging food faster with a lower life-cycle cost, less downtime, and reduced product waste requires people, technology, and processes working together to make plant efficiency and productivity the number one goal.

Conveying technology in this respect is a vital part in every food processing plant. As conveying chain and components come into direct contact with food during processing, they strongly contribute to plant process hygiene. Easy-to-clean conveying chain, based on sound hygienic design, contributes to better food safety while at the same time reducing costs through more effective cleaning. Further the reliability and robustness of the chain strongly contribute to the up time of the processing line.

Rexnord food conveying chain technology and food-safe material innovations offer high productivity solutions for food applications throughout each food manufacturing plant. That is why Rexnord’s 510, 1010, 1200 and 2010 Series MatTop® Chain, with their foodgrade design and easy-to-clean features, can be an important part of a robust and effective food safety program in every food processing plant.

Rexnord’s automotive solutions build on more than 100 years of conveying technology experience across multiple industries. From the mechanical press to the final inspection conveyors, Rexnord has developed low maintenance modular chain solutions for your applications. By assessing your individual needs and objectives, Rexnord’s skilled engineers will help you obtain the lowest Total Cost of Ownership (TCO), resulting in significant cost savings by improving operational safety, efficiency and productivity.

Rexnord 6990 Series Hybrid MatTop Chain

The 6990 Series Hybrid MatTop Chain (patent pending) is designed for automotive conveyors with high loads or frequent load variations (people movers). The steel structure in the chain creates stiffness and strength enabling the chain to be used in conveyors with lengths over 328-feet (100m) (moving people, vehicles or a combination of the two).

Rexnord 3120 Series MatTop Chain

The 3120 Series MatTop Chain is primarily used for industrial type applications: car washes, skid handling, people movers, pallet handling, and automotive parts handling. The sturdy design is molded in high-strength acetal material and utilizes Rexnord’s Twistlock pin retention system.

Rexnord 3180 Series MatTop Chain

Rexnord recognizes the importance of opportunities to easily and economically convert from existing technology in skid applications and has developed the 3180 Series MatTop Chain. These chains are suitable for 3.2 inch (81mm) skid conveyors, allowing the skids to be aligned mechanically before transferring to the next conveyor.

Successful processing in tunnel pasteurizers, warmers and coolers requires highly reliable, controlled conveying through the tunnel pasteurizer, and smooth container transfers at the infeed and outfeed. To have the highest conveying chain reliability, to eliminate product waste from tipped or broken containers, and to achieve durable conveying performance, Rexnord’s 2000-series USP MatTop chain and the Rexnord’s 9200 series Fortrex Stainless Steel MatTop Chain are specifically designed for superior performance in the demanding environment of pasteurizers, warmers and coolers.

DTS-C Dynamic In- and Outfeed Transfer

DTS-C patented by Rexnord combines special transfer combs and in/outfeed chains to the main Rexnord Pasteurizer belt for full self clearing transfers. This eliminates the dead plate area and ensures a continuous product flow eliminating back line pressure and potential product damage.

USP Ultra Stabilized Polypropylene Material

USP material is a unique formulation of stabilizers and anti-oxidants which protects the chain’s polypropylene material from degradation due to heat and/or chemicals. The USP material increases the reliability throughout the chain life cycle and helps to avoid the risk of unscheduled downtime.

PosiTrack centre guides

Patented integrated center guiding lugs ensure optimum chain tracking and keeps the chain sides from touching the tunnel structure, and eliminates the need to lock sprockets on the shaft.