< Previous Rexnord FlatTop Chains | Products index | Next Rexnord FlatTop Chains >

HP-Acetal Top Plate /Steel Base Chain

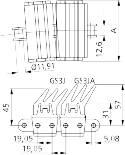

HP 1873 TAB-K325 GS2J | L1873628693 | 82.5 | 3.25 | 77 | 2.90 | 4500 | 381 | CL-63 | 36742 |

HP 1873 TAB-K450 GS2J | L1873628713 | 114.3 | 4.50 | 108 | 3.00 |

HP-Acetal Top Plate /Stainless Steel Base Chain

HP 1873 TABSS-K325 GS2J | L1873628743 | 82.5 | 3.25 | 77 | 2.90 | 3400 | 381 | CL-63 SS | 36747 |

HP 1873 TABSS-K450 GS2J | L1873628763 | 114.3 | 4.50 | 108 | 3.00 |

Standard length: 3.048 m – 10 feet (160 links). Gripper EPDM black, 45 shore A hardness.

Pag. 124

![]()

![]()

![]()

![]()

Pag. 124

![]()

Chain Type | Code Number | Plate Width A | Gripper Width C | Weight | Working Load (max.) | Sideflex Radius (min) | Connection Link | ||

mm | inch | mm | kg/m | N (21°C) | mm | Type | Code Number | ||

HP-Acetal Top Plate/Steel Base Chain | |||||||||

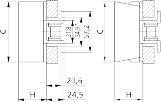

HP 1873 TAB-K325 GS3J | L1873628673 | 82.5 | 3.25 | 82.5 | 2.90 | 4500 | 381 | CL-63 | 36742 |

HP 1873 TAB-K450 GS3J | L1873631773 | 114.3 | 4.50 | 107 | 3.00 | ||||

HP-Acetal Top Plate/Stainless Steel Base Chain | |||||||||

HP 1873 TABSS-K325 GS3J | L1873628723 | 82.5 | 3.25 | 82.5 | 2.90 | 3400 | 381 | CL-63 SS | 36747 |

HP 1873 TABSS-K450 GS3J | L1873632733 | 114.3 | 4.50 | 107 | 3.00 | ||||

HP-Acetal Top Plate/Steel Base Chain | |||||||||

HP 1873 TAB-K325 GS3JA | L1873628683 | 82.5 | 3.25 | 82.5 | 2.90 | 4500 | 381 | CL-63 | 36742 |

HP 1873 TAB-K450 GS3JA | L1873631863 | 114.3 | 4.50 | 109 | 3.00 | ||||

HP-Acetal Top Plate/Stainless Steel Base Chain | |||||||||

HP 1873 TABSS-K325 GS3JA | L1873628733 | 82.5 | 3.25 | 82.5 | 2.90 | 3400 | 381 | CL-63 SS | 36747 |

HP 1873 TABSS-K450 GS3JA | L1873631873 | 114.3 | 4.50 | 109 | 3.00 | ||||

![]()

![]()

![]()

PlateTop Gripper Chains

Standard length: 3.048 m – 10 feet (160 links). Gripper EPDM grey 55 shore A hardness for GS3J K325-K450, gripper black for GS3JA K450 45 shore A hardness.

![]()

![]()

![]()

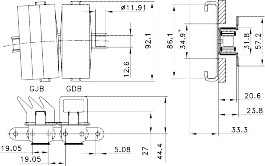

Chain Type | Code Number | Plate Width A | Gripper Width C | Working Load (max.) | Sideflex Radius (min) | Connection Link | ||

mm | inch | mm | N (21°C) | mm | Type | Code Number | ||

Steel Top Plate/Steel Base Chain | ||||||||

1874 TAB HD-K363 GDB | L1874606541 | 92.1 | 3.63 | 5.60 | 4500 | 381 | CL-63 | 36742 |

1874 TAB HD-K363 GJB | L1874606322 | |||||||

Stainless Steel Top Plate/Stainless Steel Base Chain | ||||||||

1874 TABSS-K363 GDB | L1874606581 | 92.1 | 3.63 | 5.60 | 3400 | 381 | CL-63 SS | 36747 |

1874 TABSS-K363 GJB | L1874606591 | |||||||

Standard length: 3.048 m – 10 feet (160 links). Gripper: EPDM black; 50 shore A hardness.

PlateTop Gripper Chains

Pag. 124

![]()

For steel and plastic sideflexing chains Rexnord offers the corresponding curve profiles. Without a doubt Magnetflex® is worldwide seen as the superior curve system. The programme also includes curves and straight tracks for Bevel and TAB chains.

Magnetflex® System

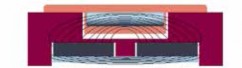

The MCC Magnetflex system has become the worldwide standard in the beverage industry. The great advantages of this system have made it the choice of the worlds leading OEMs. It is a Combi system for both plastic and steel chains. Magnets underneath the track hold the chain down in a

reliable way. Magnetflex is the only system where two magnets cover almost the complete base of the curve instead of just the track. Because the magnets are connected by a steel plate, a very broad magnetic field is being formed.

Unlike other magnetic curves this results in a force that keeps down plastic chains with steel pins just as well as steel chains. Another advantage is that this magnet position only has a slight reduction in hold-down force when the chain is being lifted, in case of pollution or broken glass, without jumping from the track. Where in other systems the chains can block and jam in the curve profile due to pollution, in the Magnetflex system the chain simply lifts slightly and keeps on running. The magnets are placed in the curve at fixed angles instead of at fixed distances to make sure that no pulsation effect is being created by the magnets, when a chain is being pulled through the curve.

The magnets make sure that all chains lie perfectly flat in the curve without tilting. In other systems the chain tension is causing the chain to use up the play in the chain guidance, causing chain edges to lift. Especially in multiple-strand curves and with high-speed conveying this means product toppling.

Another big advantage of the Magnetflex® system is the easy installation of the chains and the perfect cleanability of the system. This is due to the open and rectangular track in the curve. The chains can easily be installed from above as if the curve was a straight part of the conveyor. Also the chains can easily be

lifted from the track for maintenance and cleaning, without breaking the chain or even removing it from the conveyor construction.

Magnetflex® curves can be installed in the conveyor frame in different ways. The upper and return part can be supplied bolted together and with inserts to mount the assembled curve into the conveyor frame. The option most often used in multiple track curves is to deliver the upper and return part separately. They are then mounted against a conveyor crossbar. In this case both upper part and return part are equipped with inserts and/or holes. In both build-in options

the hole and inserts can be standard or customer specific.

Most Magnetflex® curves are equipped with a return guide shoe. This machined shoe is meant to bring the chain at the right level to enter the return part of

the curve. The position of the return guide shoe is determined by the design of the return part (level or staggered) and by the chain type. A staggered design is used when the pitch between the tracks is too small to allow the chains to run at the same level in the return. In that case two levels of tracks are made in the return part: one level in which the uneven tracks (1, 3, 5 etc.) run and one in which the even tracks run. The height of a staggered return part (usually 63 mm) is always higher than that of a non-staggered return (usually 55 mm).

Magnetflex®

curve with 2 magnets for better hold-down of the chain

Usual magnetic curve with only 1 magnet

Upper and return part bolted together

Curves and Straight Tracks

Upper and return part mounted against a cross bar

Return part at same level Staggered return part Chainbelts

®

A special execution of a Magnetflex

curve is a CIP (Cleaning in Place) curve, equipped with spraying nozzles and tubes. It is opened up as much as possible to allow

good cleaning of the steel or plastic chain and curve profile from the inside of the curve. The CIP curve can be integrated in an existing CIP system.

![]()

Magnetflex® curves are available in five different materials. The standard material, Combi-A, is a high grade of polyethylene. It is suitable for most lubricated applications with steel and plastic chains. In clean environment and with low chain speeds Combi-A can also be used in dry running applications. For dry running applications with plastic TableTop chains Combi-L and Combi-S are recommended. These materials are able to work with higher chain speeds. Combi-S has the largest application field, where Combi-L offers better noise reduction. Rexnords calculation program determines the PV (pressure-velocity) load on the curve in a specific application and will advise in which application load and speed require Combi-L or Combi-S curves. For lubricated, abrasive applications (filler discharge) or abrasive, dry run- ning applications (glassworks) with (stainless) steel chains, Combi-G is most suitable. This ceramic reinforced polyethylene offers an extremely good wear resistance. New Generation Combi-X curves can be applied in high speed (dry running) applications.

For the most demanding bottling and container applications, there is no substitute for the performance and productivity of Rexnord TableTop and MatTop Chains. Since 1938, with the ground-breaking 815 TableTop stainless steel straight-running chain, Rexnord has pioneered innovation in beverage and food conveying that has inspired loyalty and driven specification for Rexnord conveyor chains from customers around the globe.

Line efficiency

Smooth container flow at high speeds is essential to increase line efficiency and preventing product damage. Especially when moving from multiple to single lanes or the reverse, the gentle slide of bottles across ultra-flat, highly polished stainless steel Rexnord chain can contribute significantly to the quality and efficiency of your beverage production line.

Applications in beverage

Rexnord products cover a wide variety of applications like: general conveying of glass bottles one-way and return, PET bottles and other plastic containers, jars, cans 2- and 3-piece, crates, plastic containers, boxes, shrink-wrapped packages.

Product Portfolio

Rexnord offers a comprehensive of conveyor products which include

Metal TableTop chain

Plastic TableTop chain including LBP and Supergrip

Plastic MatTop chain in standard, small pitch and heavy duty alternatives.

Magnetflex Corner tracks as well as alternatives like Tab and Bevel curves

Machined and moulded sprockets

High performance polymer materials & economic alternatives for less demanding applications

Pack and case conveying that offers flexibility of line configurations and total system cost efficiencies can significantly improve productivity at the dry end of filling lines. At the same time, brand extensions, innovative packaging, and light weight packaging materials are driving more demanding performance in pack and case handling. Cases and packs must be protected from damage even as they move rapidly out of case packers and shrink wrap machines and into, around, and out of curves.

That’s why Rexnord’s case and package handling conveying chains come in our modular small pitch, lightduty 15mm 1500 Series to medium duty 25.4mm pitch 1000 Series to the heavy-duty 1 in pitch 1005 Series in both versions for general conveying and in Super Grip / RubberTop™ versions for metering, incline, decline and braking applications. Furthermore the programm includes a comprehensive portfolio of Sideflexing MatTop chains like the versatile 1200-series MatTop. For accumulating conveyor the LBP (Low Backline Pressure) chains offers a solution to a large variety of applications.

With the Rexnord original Heavy Duty TableTop chains for packaging conveying, no other company provides the breadth of conveying solutions for your case and package handling requirements.

Rexnord products are known for their reliable performance in though conditions and challenging applications due to their robustness in design and drive technology. In container making therefore Rexnord products are often the preferred choice for applications like vacuum elevators, high speed (magnetic) conveyors, UV applications, high temperature applications and inspection conveyors.

Rexnord Material innovation

On top Rexnord offers the most comprehensive material portfolio in the market to meet an extensive variety of application requirements. Several applications in glassworks and container making lines combine an abrasive environment with the need for smooth container handling. Often these applications can not be easily lubricated to neutralize the effect of the hard abrasive particles in the environment. Therefore specialized materials can be part of a custom made solution. This is why, besides several proven specialized high performance materials like WX, HP and PS, Rexnords material portfolio is now completed with DKA aramid reinforced material.

Processing and packaging food faster with a lower life-cycle cost, less downtime, and reduced product waste requires people, technology, and processes working together to make plant efficiency and productivity the number one goal.

Conveying technology in this respect is a vital part in every food processing plant. As conveying chain and components come into direct contact with food during processing, they strongly contribute to plant process hygiene. Easy-to-clean conveying chain, based on sound hygienic design, contributes to better food safety while at the same time reducing costs through more effective cleaning. Further the reliability and robustness of the chain strongly contribute to the up time of the processing line.

Rexnord food conveying chain technology and food-safe material innovations offer high productivity solutions for food applications throughout each food manufacturing plant. That is why Rexnord’s 510, 1010, 1200 and 2010 Series MatTop® Chain, with their foodgrade design and easy-to-clean features, can be an important part of a robust and effective food safety program in every food processing plant.

Rexnord’s automotive solutions build on more than 100 years of conveying technology experience across multiple industries. From the mechanical press to the final inspection conveyors, Rexnord has developed low maintenance modular chain solutions for your applications. By assessing your individual needs and objectives, Rexnord’s skilled engineers will help you obtain the lowest Total Cost of Ownership (TCO), resulting in significant cost savings by improving operational safety, efficiency and productivity.

Rexnord 6990 Series Hybrid MatTop Chain

The 6990 Series Hybrid MatTop Chain (patent pending) is designed for automotive conveyors with high loads or frequent load variations (people movers). The steel structure in the chain creates stiffness and strength enabling the chain to be used in conveyors with lengths over 328-feet (100m) (moving people, vehicles or a combination of the two).

Rexnord 3120 Series MatTop Chain

The 3120 Series MatTop Chain is primarily used for industrial type applications: car washes, skid handling, people movers, pallet handling, and automotive parts handling. The sturdy design is molded in high-strength acetal material and utilizes Rexnord’s Twistlock pin retention system.

Rexnord 3180 Series MatTop Chain

Rexnord recognizes the importance of opportunities to easily and economically convert from existing technology in skid applications and has developed the 3180 Series MatTop Chain. These chains are suitable for 3.2 inch (81mm) skid conveyors, allowing the skids to be aligned mechanically before transferring to the next conveyor.

Successful processing in tunnel pasteurizers, warmers and coolers requires highly reliable, controlled conveying through the tunnel pasteurizer, and smooth container transfers at the infeed and outfeed. To have the highest conveying chain reliability, to eliminate product waste from tipped or broken containers, and to achieve durable conveying performance, Rexnord’s 2000-series USP MatTop chain and the Rexnord’s 9200 series Fortrex Stainless Steel MatTop Chain are specifically designed for superior performance in the demanding environment of pasteurizers, warmers and coolers.

DTS-C Dynamic In- and Outfeed Transfer

DTS-C patented by Rexnord combines special transfer combs and in/outfeed chains to the main Rexnord Pasteurizer belt for full self clearing transfers. This eliminates the dead plate area and ensures a continuous product flow eliminating back line pressure and potential product damage.

USP Ultra Stabilized Polypropylene Material

USP material is a unique formulation of stabilizers and anti-oxidants which protects the chain’s polypropylene material from degradation due to heat and/or chemicals. The USP material increases the reliability throughout the chain life cycle and helps to avoid the risk of unscheduled downtime.

PosiTrack centre guides

Patented integrated center guiding lugs ensure optimum chain tracking and keeps the chain sides from touching the tunnel structure, and eliminates the need to lock sprockets on the shaft.